What Is A Drive Belt Tensioner? Why Does It Need Replacement?Ī drive belt tensioner or an idler pulley is a component in the engine bay that maintains tension on the drive belt - which could be a serpentine belt or v-belt. Here are answers to four queries on drive belt tensioners and their replacement: 1. These problems will also be highlighted by the lit warning lights mentioned above.īoth are a sign that your drive belt tensioner needs a replacement.Ĥ FAQs On Drive Belt Tensioner Replacement Performance ProblemsĪ failing tensioner may lead to alternator issues or performance problems in certain elements of your car, like the water pump, power steering, and air conditioning. If that happens, you might have to get the drive belt tensioner assessed at your local auto repair shop. In this case, certain dashboard warning lights, like the check engine light and battery light, may turn on. When the drive belt loses tension, your vehicle may experience issues, like charging failure and engine overheating. So, it’s best to get a belt tensioner and drive belt replacement as soon as possible. If ignored, tensioner housing cracks could result in belt failure or destroy parts in front of it, like the radiator.Īdditionally, a worn-out belt tensioner pulley or tensioner spring won’t apply proper belt tension, making the belt lose functionality. This wear and tear may also appear in the form of rust or cracks on the tensioner housing or a loose tensioner arm. On inspecting the drive belt, you may discover visible belt wear and tear. Tip: Note the belt noise you hear and mention it to the mechanic when taking your vehicle for any servicing. If it’s not the tensioner, you could have a bad serpentine belt or v-belt.

So, if you hear a worrying noise coming from your vehicle’s engine bay, you may want to have its drive belt tensioner checked out.

#Chrysler 2.4 timing belt tensioner installation verification#

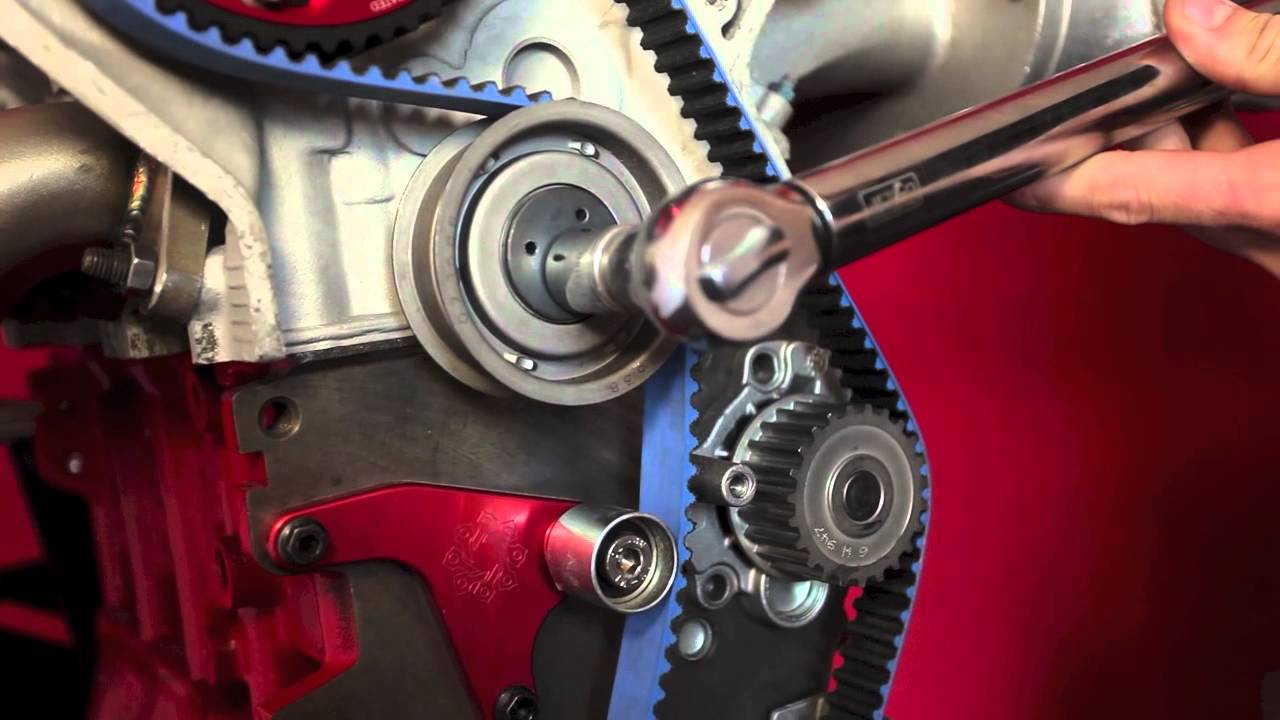

Do not rotate crankshaft counterclockwise as this will make verification of proper tension-er setting impossible.ħ) Rotate the crankshaft clockwise two complete revolutions manually for seating of the belt, until the crankshaft is re-positioned at the TDC position. If TDC is missed, rotate a further two revolutions until TDC is achieved. NOTE : Re-positioning the crankshaft to the TDC position must be done only during the clockwise rotation movement.

Setting notch and spring tang should remain aligned after lock bolt is torqued.

Using the Allen wrench to prevent the top plate from moving, torque the tension-er lock bolt to 25 Nm (220 in. Watching the movement of the setting notch, continue rotating the top plate counterclockwise until the setting notch is aligned with the spring tang. The tension-er pulley will move against the belt and the tension-er setting notch will eventually start to move clockwise. 1) Set crankshaft sprocket to TDC by aligning the sprocket with the arrow on the oil pump housing.Ģ) Set camshafts timing marks so that the exhaust camshaft sprocket is a half notch below the intake camshaft sprocket.Įnsure that the arrows on both camshaft sprockets are facing up.ģ) Starting at the crankshaft, go around the water pump sprocket, idler pulley, camshaft sprockets and then around the tensioner.Ĥ) Move the exhaust camshaft sprocket counterclockwise to align marks and take up belt slack.ĥ) Insert a 6mm Allen wrench into the hexagon opening located on the top of the belt tension-er pulley.

0 kommentar(er)

0 kommentar(er)